Page:Home » Company » Innovation »

01/Advanced foil air bearing design concept

The company uses the actual engineering experience of foil bearing development and draws on the advanced bearing design concept from abroad to form a mature and independent foil air bearing design process.

02/Design capability for a full range of foil air bearings

The company has a diameter: Φ 12-Φ 100, speed: 20000-120000rpm rpm range of full-size series foil air bearing design, radial bearing capacity of up to 200Kg, thrust bearing capacity of up to 60Kg.

03/Self-developed foil bearing performance simulation calculation software

Developed simulation software for radial foil bearings and thrust foil bearings that can meet practical engineering applications, greatly reducing development cycles and reducing development costs.

04/First-class bearing manufacturing process work

Through years of exploration, the company has developed advanced processing technology for foil air bearings.

05/Advanced bearing inspection technology

The company has introduced many sets of advanced optical inspection equipment from abroad to ensure the precision of processing and manufacturing of foil bearing components.

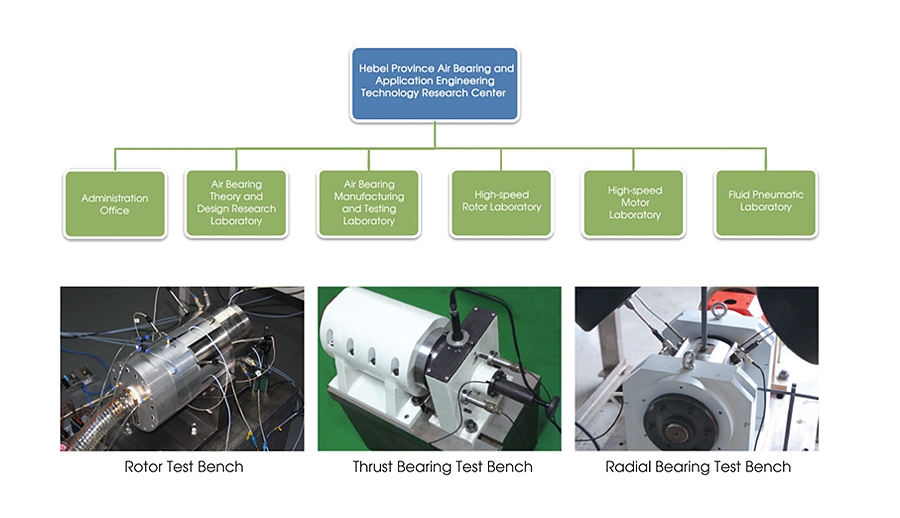

06/System foil bearing test plan design

The company has the ability to design, build and commission a complete bearing performance test platform tailored to the customer's actual needs.

07/High-temperature coating technology with excellent performance

At present, the company has mastered the low temperature coating technology below 300 °C and the high temperature coating technology in the range of 300 °C ~ 500 °C. The bearing start and stop life is up to 20,000 times.